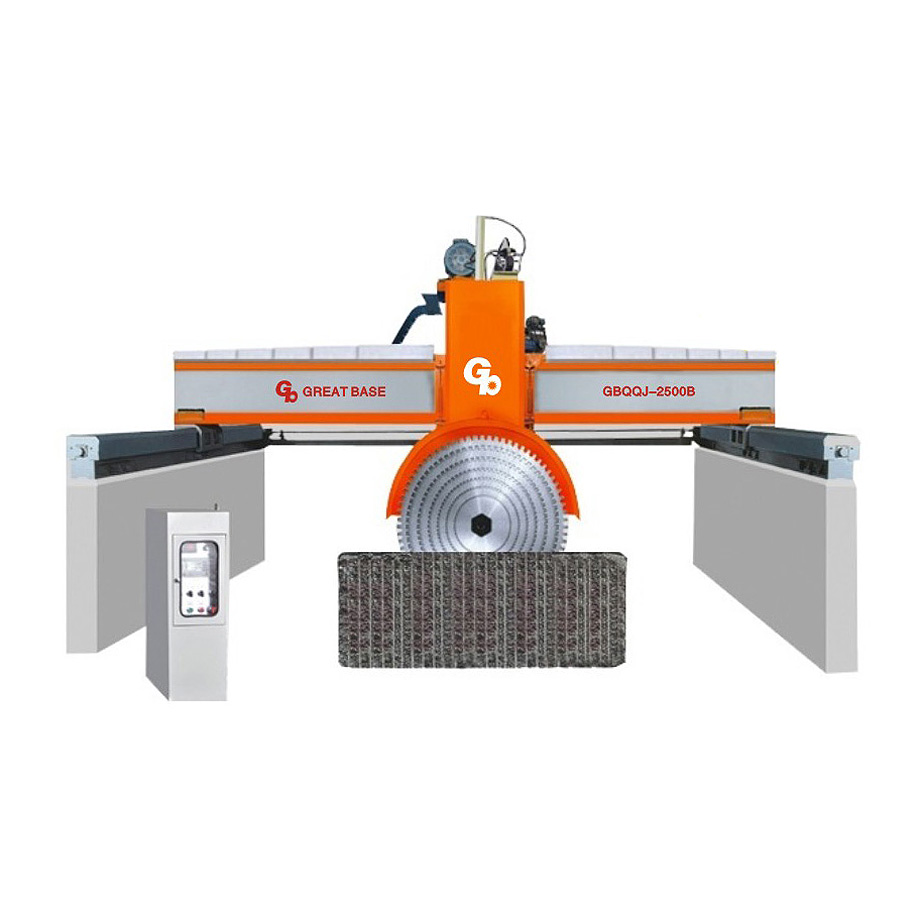

Bridge Type Hydraullic Up/Down Stone Cutting Machine GBQQJ-1800/2000/2200

- Great Base

- CHINA

- 30 days

- 20sets per month

Great Base (GB machine) GBQQJ series Bridge Type Hydraulic Up/Down Stone Cutting Machine is manufactured by our GREAT BASE factory, mainly used to cut granite (also marble, sandstone,artificial stone )blocks into slabs. GBQQJ is with high precision and lower maintenance, current most popular stone cutting machine in the market, we have several types with blade quantity 1 piece to 26 pieces, GREAT BASE (GB machine) worked in stone processing machine industry nearly 20 years, our GREAT BASE (GB machine) different types stone processing machine working in more than 60 countries and we have several partners in different countries or area.We can provide professional solution and good service for all of our abroad clients about stone cutting, polishing, edge cutting, special shape processing and etc.

The most hot and popular Multi Disc Stone Cutting Machine

Introduction : Great Base (GB machine) GBQQJ Bridge Type Hydraulic Up/Down Stone Cutting Machine is widely used in current modern stone processing factory, bridge type and without trolley, so you can put your block on the floor directly, crossbeam on the left and right rails, slicing by lead screw, with lower maintenance require, double lead screw ensure high precision and long use age. Cutter head up/down is by four pieces steel column and double hydraulic cylinder with high efficiency, encoder to calculate cutting thickness, cutter head up/down movement,cutter head right/left movement, PLC control and touch screen operation realized full automatic cutting, single blade or multi blade will be suitable for your all purpose of stone processing.

Specification:

|

GBQQJ-2000 |

GBQQJ-2200 |

||

|

Crossbeam size |

mm |

7500x530x600 |

7500x530x600 |

|

Main motor |

kw |

45 |

45 |

|

Feeding Motor |

kw |

4 |

4 |

|

Hydraulic Up/down motor |

kw |

4 |

4 |

|

Slicing Motor |

kw |

2.2 |

2.2 |

|

Max.cutting size |

mm |

3500x2000x850 |

3300x2000x950 |

|

Cutter head up/down stroke |

mm |

1100 |

1250 |

|

Max.Quantity of saw blade |

1--9pcs, Max.D.2000mm |

1--9pcs, Max.D.2200 |

|

|

Total weight |

kgs |

About 10000 |

About 10200 |

Advantage of GB machine

1) GREAT BASE products 90% is for export, China machine make stone GBQQJ Bridge Multi Blade Cutter ’s main beam, head stock, up/down system top and bottom plate all are heavy duty, thick, processed well iron casting material,

2) Granite machine Adopting advanced world famous brand components in electric parts .

3) China bridge cutter GBQQJ series granite cutting machine adopts special design for the up/down parts, head stock and axis, all these design is improved based on our experience in domestic and abroad clients’ feedback, ensure higher production capacity and higher precision.

4) We are professional stone processing machine supplier located in XIAMEN, CHINA, nearly 20 years in stone processing machine industry

More detailed machine parts photos:

Main usage and data:

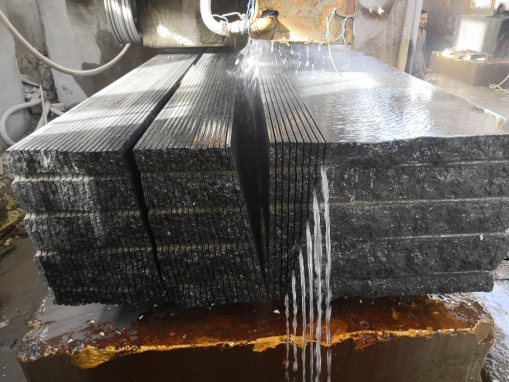

This machine is mainly for cutting granite/marble or other nature stone blocks into slab, then the slab will go to polishing machine, or bush hammer machine, or honing machine or flaming machine or cut to size bridge cutting machine or manual edge cutting machine to cut into the size you want. it can be single piece blade or multi disc.Cutting capacity can be 50M2 or 400M2 per day. Blade size can be D.1600mm to D.3500mm. So this machine can meet different cutting requirements for different client.

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

FAQ

1. Do you have more stone machines?

Yes, we can produce all series of stone processing machines with competitive price and high quality.

2. Do you have agent?

We don't have agent as we all sell directly to our customer, in this way, the customer can get lowest cost.

3. How much is this machine?

Please tell me your stone is granite or marble, the size, your destination port, so that I can quote you best price.

4. How long can I get my product?

Normally it takes 30 days to produce our products.